7 Lesser Knows Applications Of Teflon

Teflon is a standard tool, and many people know it owing to its most straightforward applications that is visible daily. For those who don’t have an idea about where this is going, look around your kitchen. You might have recently discovered the rise of ‘non-stick’ pans and other utensils at your home. What makes these utensils ‘non-stick’?

So, Teflon is a coating on the pans, pots, and other utensils to make them resist temperature issues, corrosion, and heat. It works as an additional layer that helps to create a low-friction cooking surface, and the results are excellent. Food does not stick to utensils, so the quality is secured. Also, there is less use of oil and hence, low fat intake by the body.

But are these the only reasons for the hype behind Teflon? If you ever get a chance, visit a PTFE parts manufacturer and see the immense uses of teflon you might not have even guessed earlier.

Lesser Known Teflon Applications

The diversified purposes help it improve its visibility in various commercial sectors. Some of them are discussed as follows:

1. Personal Care Products

Source: Unsplash

Who knew such coatings could make it to the personal care products family and industry, too? Are you curious about the coated products that provide efficient use?

Well, ring a bell!

Curling irons and hair straighteners have been a part of the market for a long. They provide a seamless shine on each hair strand, and the coating has a significant role to play in it.

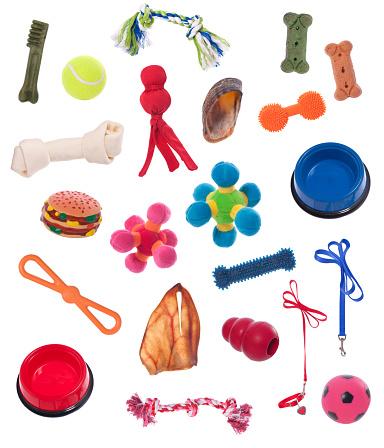

2. Pet Industry Service Applications

Source: Unsplash

With the rising degree of awareness related to animal welfare, people are also open to adopting pets of local breeds. Hence, there is a domestic rise for the products that help to give these animals a good life. For example, pet toys are in great demand. Manufacturers can coat the toys with this coating and sell dishes with this layer that add to the product’s life without harming the animal.

3. Food Industry

The love for cheese knows no bounds. But what if the cheese molds don’t have a proper layer? The quality will be problematic, and you might stop eating cheese. But, thanks to the PTFE coating, cheese molds are secure. The teflon coatings are thus also helpful in food processing.

4. Car Parts

Automakers and car part manufacturing companies are coming up with the coating used for carburetor parts, bypass shafts, and automotive plungers. Apart from that, the coatings can be used in COB LED strips, too. Customers can choose this one for beneficial and long-term use.

5. Commercial And Retail Sector

Source: Unsplash

Commercial and retail activities are on the rise due to industrialization. It is incomplete without skilled labor. Maintenance is needed, but you can reduce the costs by using quality things like Teflon. For example, if you indulge in building escalators, you can use the kick panels with durable and qualitative coatings.

6. Energy Sector

The rise of the energy sector is imperative to meet the rising requirements on a global scale. Solar panels are being installed at a large scale, and Teflon is a significant consideration for the same. They are here to stay, so it is essential to add a sturdy layer, and Teflon does the needful.

7. Construction Industry

The construction industry has been expanding for many years, and it is looking for options to add layers that can ensure sturdiness in the processes. For example, Teflon can be used for covering drill parts and tools.

Considerations For Selection

The use is expected, but the material, quantity of the application, wide range of characteristics, and the specified product use. Also, the differentiation might lie in the form of use. It means Teflon can be used in powder form and even in liquid form. It will also alter the application of coating. Hence, you should try and cater to some considerations for selection that are as follows:

- What kind of surface is to be coated? The application shall be different on metallic and non-metallic surfaces.

- What is the degree of chemical resistance required?

- Whether the product is strict or not and whether there is a proper degree of friction present.

- Also, you should check the appropriation of the abrasion resistance and use conditions.

At last, you should look into the functions of anything that you plan to do PTFE coating upon. For example, the form of coating and the process will be different for products belonging to the medical plastic injection molding companies, than the Teflon coated products belonging to the manufacturing, and commercial industries. Also, if it is an industrial product, you should inquire about it. All these factors are essential; hence, you should not miss them.

Conclusion

Teflon helps to obtain lubricated services and renders other benefits like chemical resistance and protective barriers on various products and assets. Hence, thanks to the endless possibilities, the customers can benefit immensely from it.

Apart from this if you are interested to know more about A Full List of Services Offered by Immigration Lawyers then visit our Law category.